Magnetic Abrasive Finishing

VEDA Group of Companies offers a unique method of magnetic abrasive finishing (MAF) with "semi-fixed" abrasive used for uniform and high-quality processing of irregular shaped objects.

The uniqueness of MAF:

- use of magnetic abrasive powder composite materials with specific properties in weak magnetic fields;

- special kinematics of instrument movements.

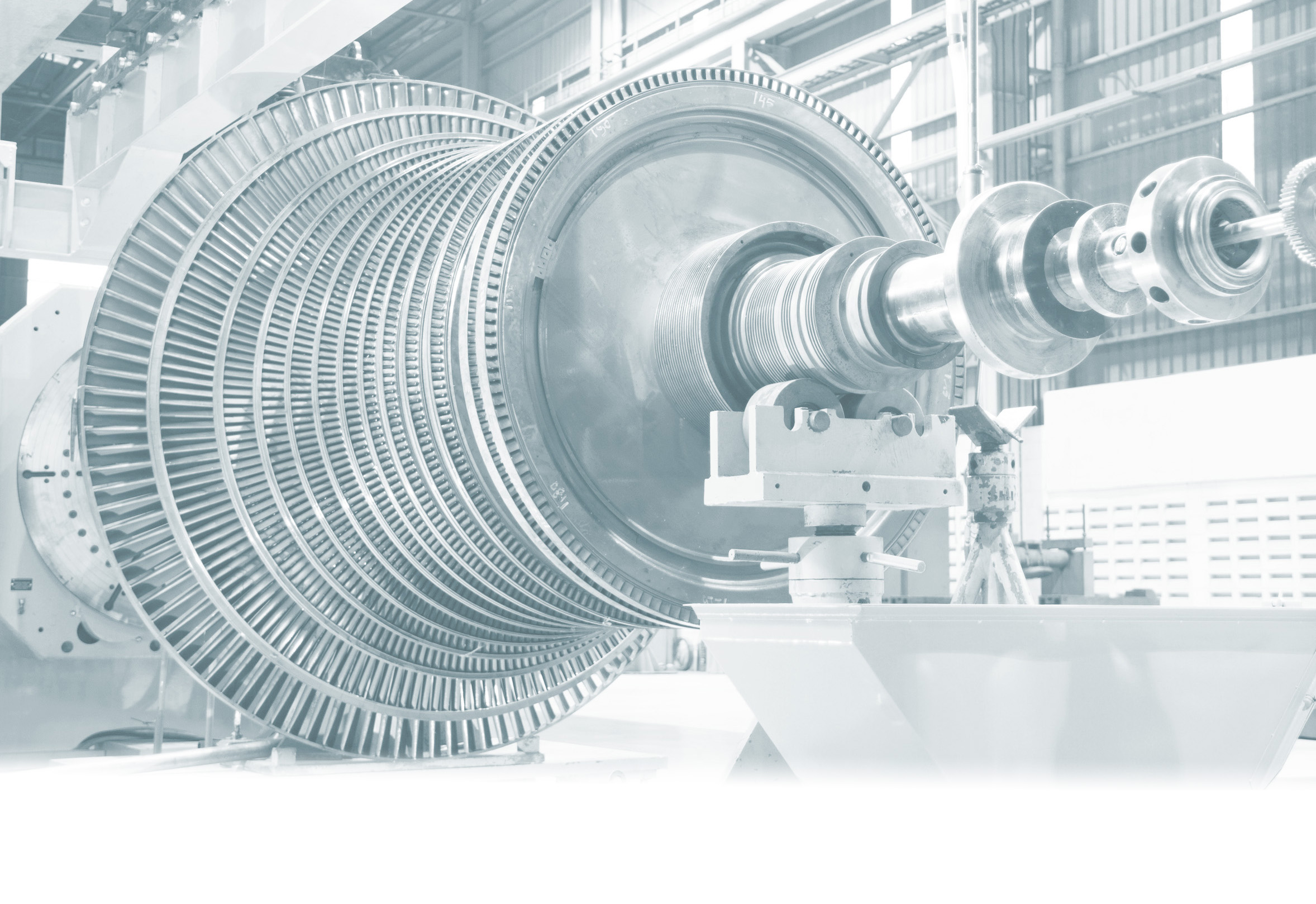

Application of MAF - finish machining during production, repair, strengthening and restoration of the following parts and tools:

- turbine blades

- end cutting tools

- throwaway carbide indexable inserts

- gear-like parts

- helical surfaces

- saws

- etc.

Can be carried out finishing of magnetic and nonmagnetic materials.

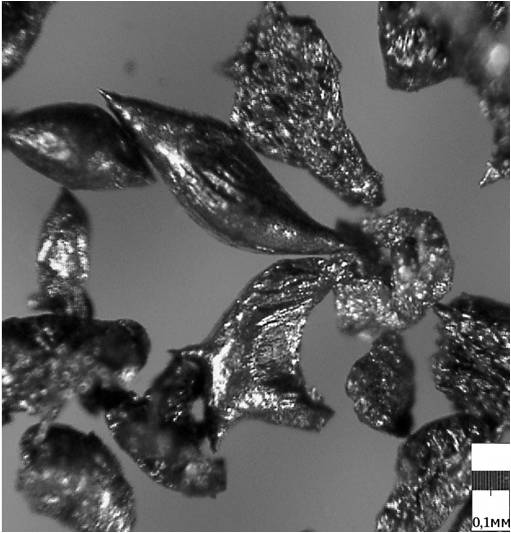

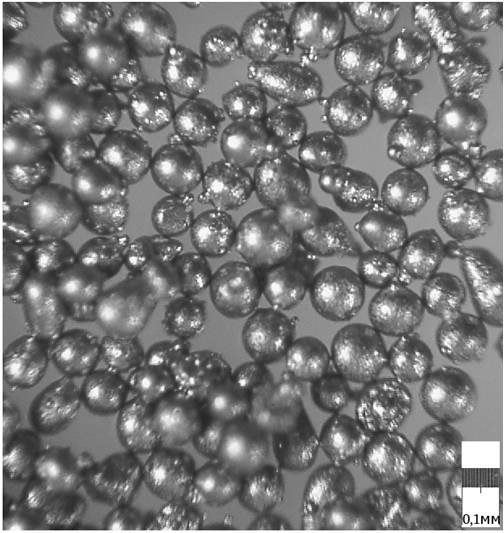

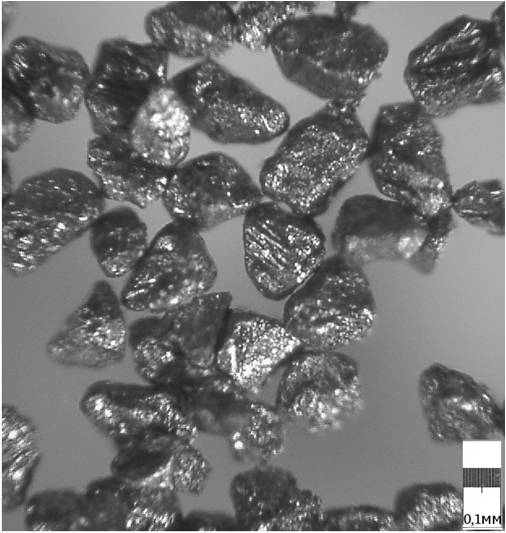

Powders for Magnetic Abrasive Finishing

Technical advantages:

- Ensuring the undulation of irregular surfaces of Ra <0.1-0.2 microns for a wide variety of materials, such as alloys of aluminum, copper, titanium, magnesium, structural and special steels, special heat resistant and sintered hard alloys, technical ceramics, etc.

- Providing a surface layer with increased hardness, compressive residual stresses and gradient structure.

- Increased durability of cutting tools by at least 1.8 times.

- Increased fatigue strength of aircraft engine blades by 15-18%.

- Sizing when forming thin edges on blades and cutting tools.

- Rounding tooth tips of the gear teeth.

- 4-5 times better productivity compared with conventional grinding and polishing techniques.

- Uniform hardening of machined surfaces.

- Preparation of surfaces for CVD and PVD coating.

- Working with products with thin coatings, removing defects, hardening of coated parts.

Economic benefits:

- Elimination of unproductive manual labour

- Automated finishing process

- Automated polishing process

- Improved tool quality

- Restoration of old tools

- Increased service life of tools, savings on new tool purchases.

Tools that can be processed by MAF:

- shanks

- milling cutters (cylindrical, disc, end, face, angular, etc.)

- shaped cutters

- reamers

- broaches

- thread cutting tools

- grooves

- brackets

- measuring plugs.

Customized MAF solutions can be developed and implemented by agreement with the customer.