Power engineering

Products manufactured by VEDA group of companies has been widely used in power engineering.

VEDA Group of Companies is proud to offer vibration measurement systems and systems for control and monitoring for complex technical objects. These products have been manufactured since 1996 under the trademark Vibro-Shield.

Our systems were installed on every power plant of the USSR, as well as on gas pumping stations, refineries and various metallurgical and chemical plants.

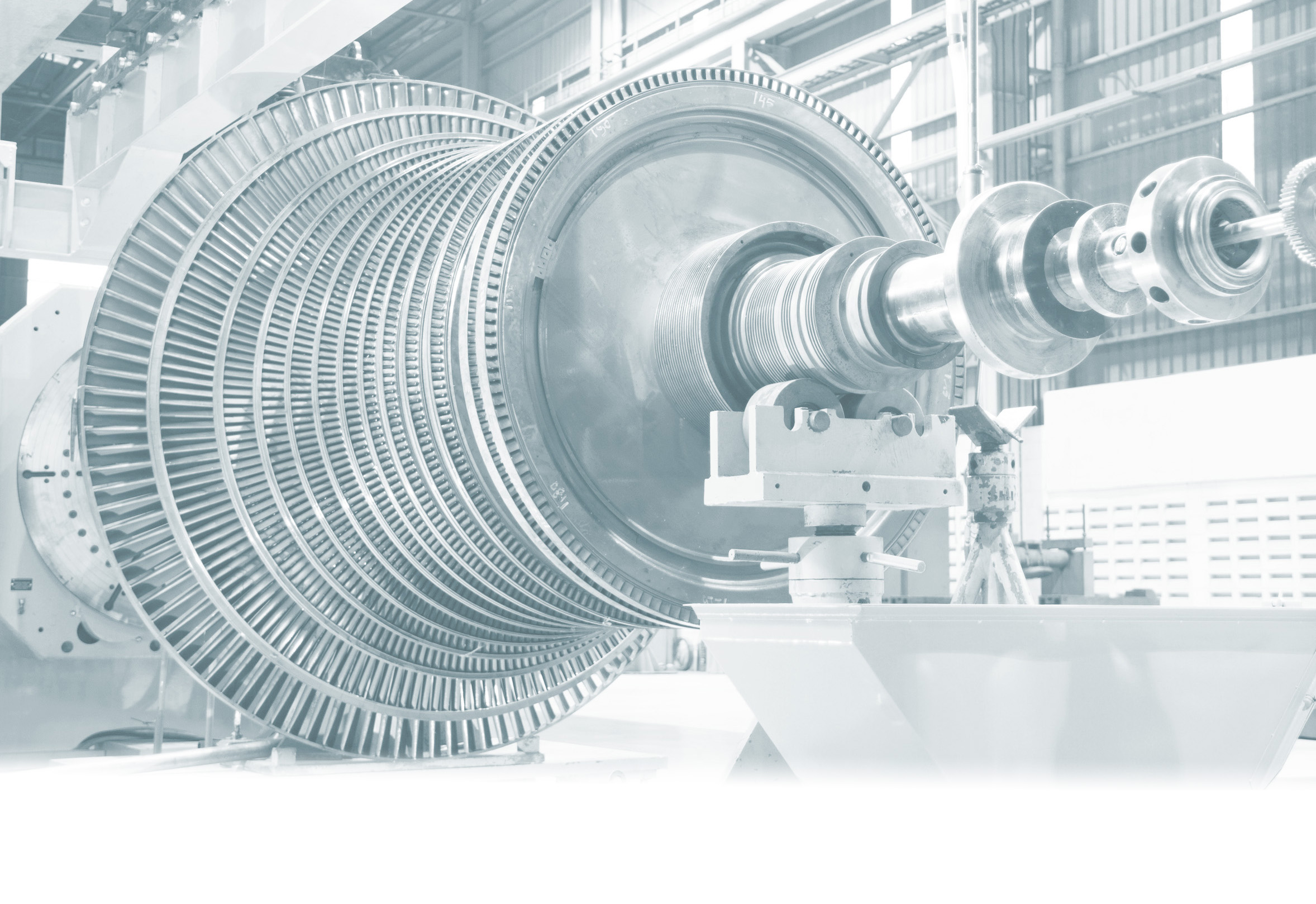

Vibration measurement systems

Vibration - is harmonic equipment oscillations caused by external factors that lead to a reduction in operational reliability and service life of machinery.

Continuous monitoring of vibration parameters and timely identification of incipient defects operated equipment allows, on the basis of historical data to predict the onset of an emergency and conduct preventive or scheduled maintenance equipment. Submitted vibration measurement system used to determine the current condition of the objects.

VEDA Group presents the following vibration measurement system:

– KSA-15 control and alarm system is a stationary system designed for continuous measurement and monitoring of vibration parameters on the rotating parts of the machine during its start-up and under load.

Application: gas compression and oil refineries.

– VVK-331 Control and Alarm Device – stationary equipment for continuous measurement and control of non-pulse fixed vibrations on non-rotating parts of the machine during its start-up and under load.

Application: power generating station (NPP, HPP, TPP, HPP, TPP and others).

– Integrated control and monitoring systems for complex technical objects – the system is used for monitoring the technical parameters of the machinery in real time.

Application: complex technical objects that require monitoring state operated equipment.

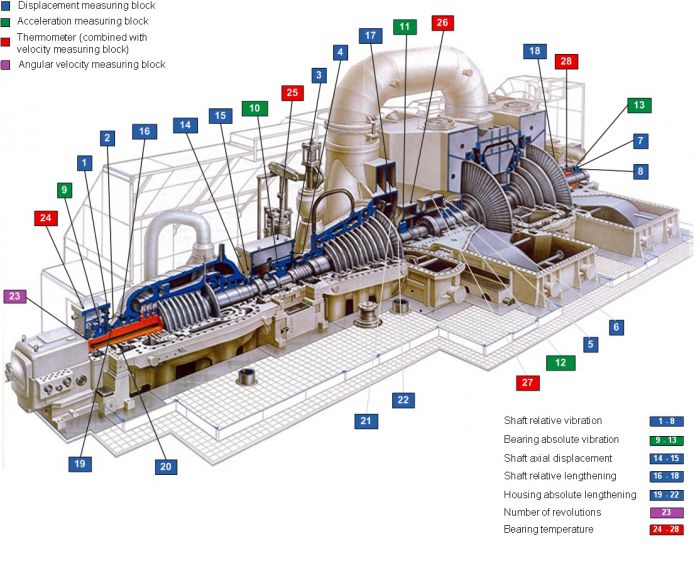

SenSystem - integrated control and monitoring systems for complex technical objects

The system features sensors for measuring vibration speed, vibration displacement and angular velocity. The monitoring equipment controls the modes of the sensors and reads the measurement data.

The monitoring and control equipment is responsible for storing, processing and displaying the data, alarm and protection alerts.

Features:

· calculation of the basic parameters of vibration control

· additional data processing in real time

· displaying the measured data

· emergency alarm

· long-term forecast of the object’s condition

· storing the measured data in the electronic database,

· remote database access according to the access rights for management and technical specialists.

The figure shows an example of the turbine with installation points for the measurement sensors of the monitoring system.

- reliability

- ease of installation

- convenient operation and maintenance

- long service life.